Quick Connectors for LED Light Strips

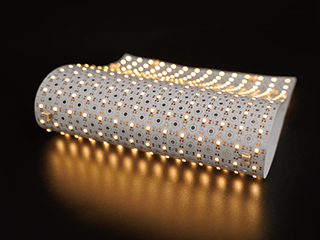

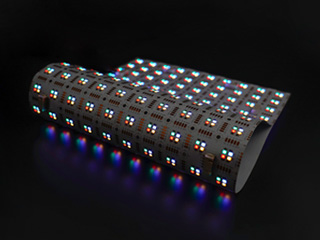

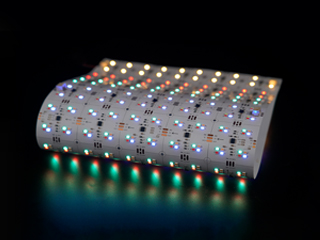

Traditional waterproof LED light strips are constrained by their structural design, requiring electrical connection or inter-strip connection exclusively through soldering. This process involves soldering wires, applying adhesive, and sealing with waterproof end caps, followed by waiting for them to dry. It is a complex operation that demands skilled soldering techniques and requires a drying period.

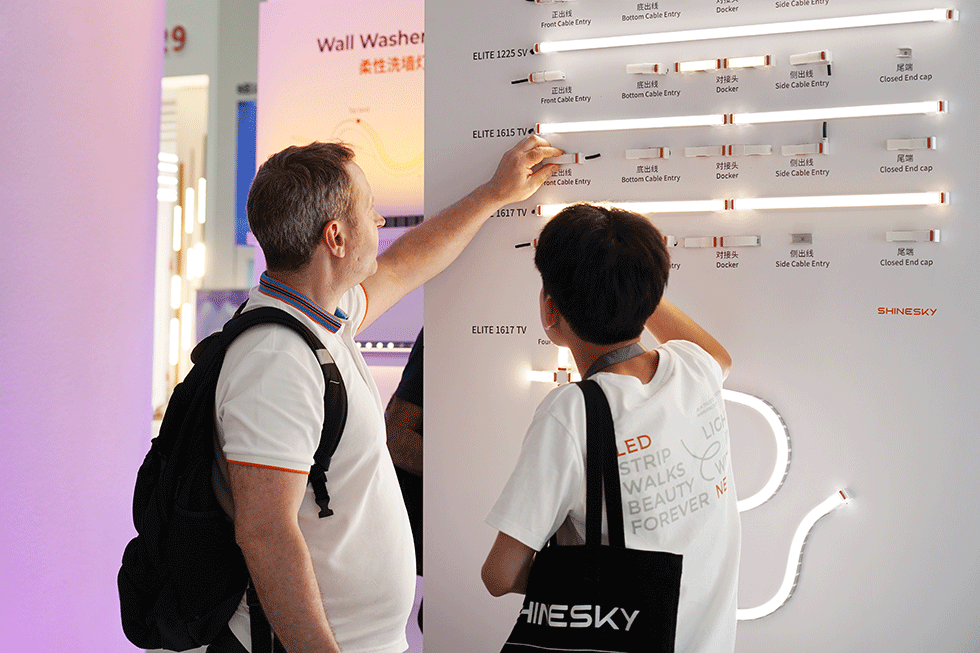

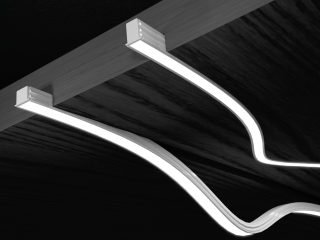

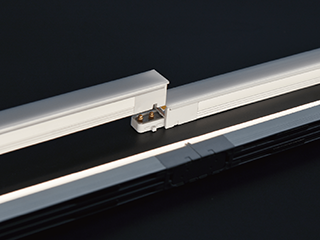

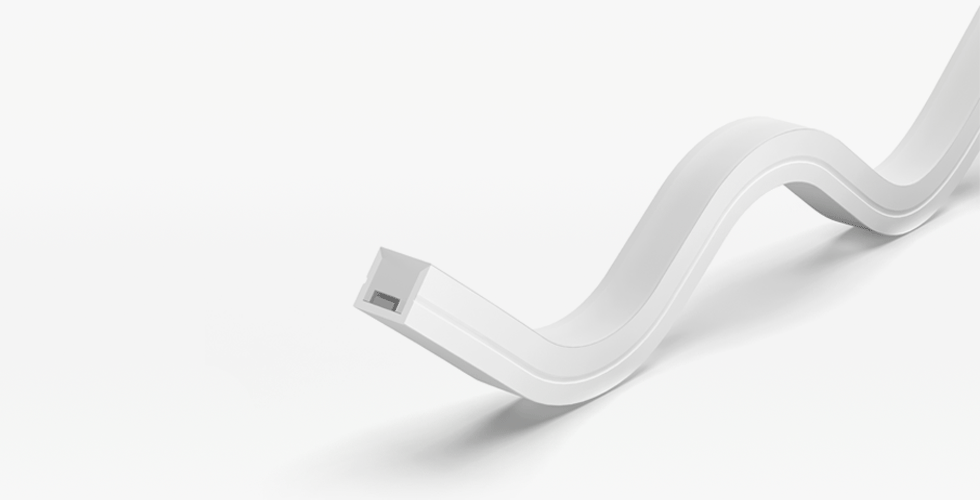

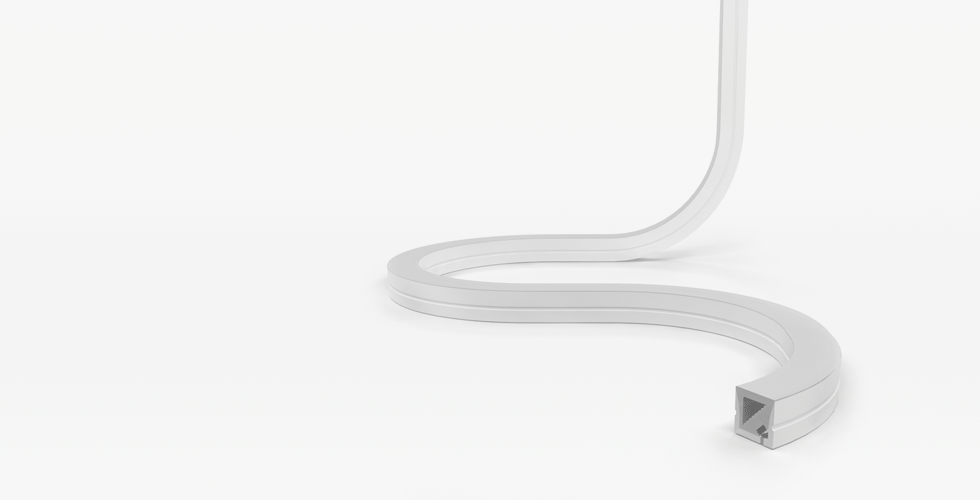

In contrast, this quick connector enables the LED light strips to be customized in length according to the site’s environment without the need for any tools to complete the end caps installation. Key advantages include multiple configurations such as different cable positions, front output, bottom output, side output, and close end cap options. With most accessories interchangeable except for the outlet end caps, stocking is simplified, and installation is quick and convenient.